Partner with Reveation Labs today and let’s turn your business goals into tangible success. Get in touch with us to discover how we can help you.

Sara Ali

16 Dec 2025

Your ERP says 240 units in stock. Your warehouse system shows 186. Meanwhile, your website just sold 50 units to a customer who expects delivery next Tuesday.

In three hours, your fulfilment team will short-ship an order to your second-largest account. They'll have no idea why the numbers don't match. Again.

Sound familiar?

Most B2B supply chain manufacturers don't lose business because of bad products. B2B supply chain distributors aren't struggling because of weak sales teams.

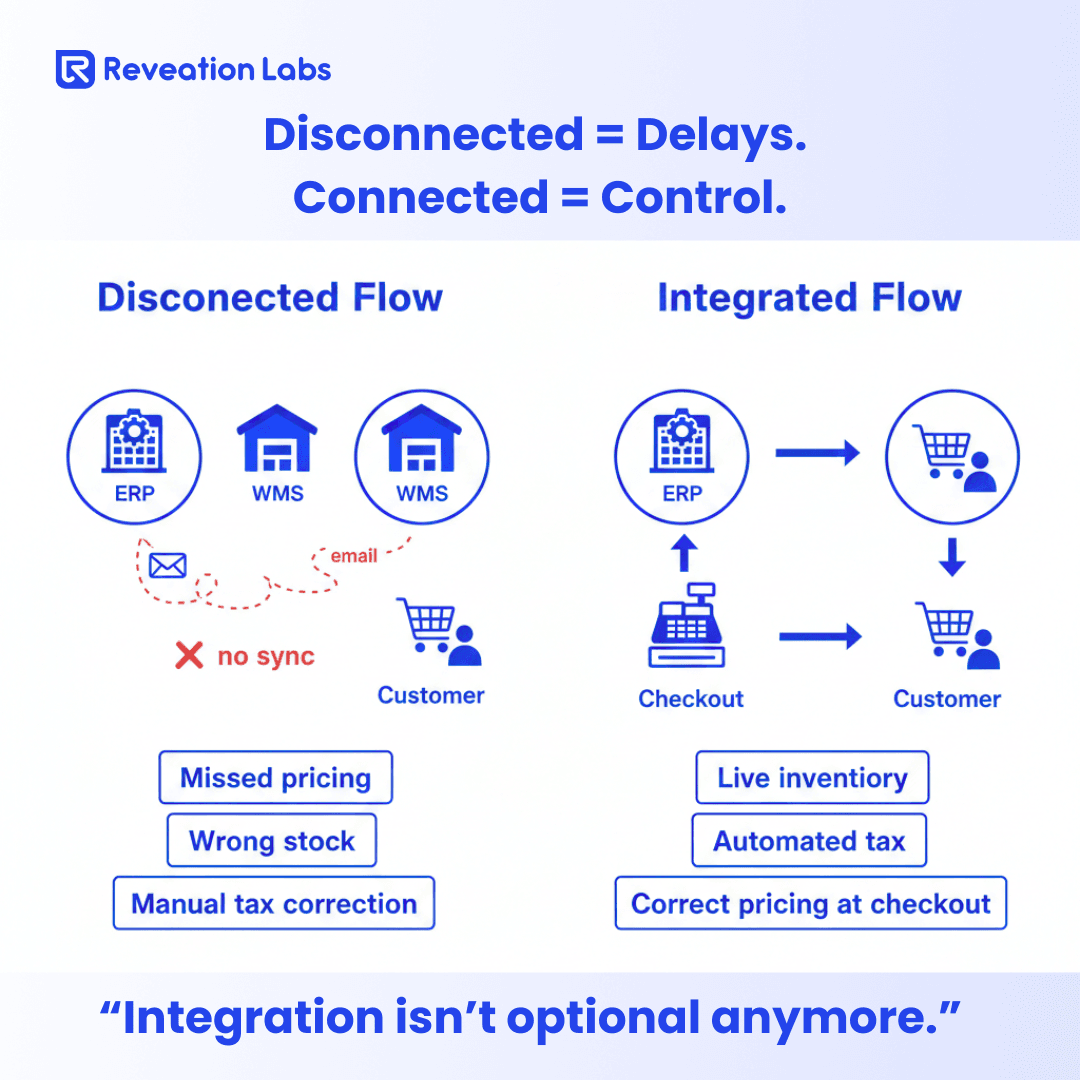

They're bleeding money because the systems that should talk to each other simply don't.

And that disconnect costs more than you think.

Here's what the data shows. Manual data entry errors hit 4% across supply chain operations. For a business processing 10,000 transactions monthly, that's 400 mistakes every single month.

Think about what each error actually costs you.

An overstock situation that ties up cash. A delayed shipment that triggers penalty clauses. A pricing mistake that requires credits and explanations.

Research shows that if each error costs just $50 to fix, you're burning $240,000 annually on preventable mistakes.

But here's the real number. When you add labor costs, missed revenue opportunities, and emergency freight charges, many B2B supply chain manufacturers see this number exceed $600,000 per year.

The core issue isn't that you have ten different problems. You have one problem with ten symptoms.

Your business logic lives in Excel spreadsheets and email chains instead of automated workflows connecting your ERP, warehouse system, and website.

Most software vendors promise their solution will fix everything. Then you end up managing 11 different logins. Your team exports 7 CSV files manually every morning. Each new system adds complexity instead of clarity.

Your team becomes the integration layer, manually moving data between platforms that refuse to talk to each other.

Here's what makes this harder for B2B supply chain distributors. You're not running a simple retail operation.

You're managing contract pricing that varies by customer, by product, by volume tier, and by date range.

Freight calculations depend on carrier, delivery zone, weight breaks, and fuel surcharges that change weekly.

Tax exemption certificates vary by state, product category, and customer entity. Multi-location inventory involves transfer orders, consignment arrangements, and drop-ship rules.

Orders require custom compliance documents like Material Safety Data Sheets or Certificates of Analysis.

According to recent industry data, 63% of logistics firms are now investing in supply chain visibility platforms.

The reason? The competitive advantage for B2B supply chain manufacturers isn't in individual software tools. It's in how seamlessly those tools connect.

Your sales rep checks inventory and sees 185 units available. A customer places an online order for 100 units. When the warehouse picker opens their system, only 47 units show up.

Now you're 53 units short. The scramble begins.

This happens because your ERP records purchases and sales transactions while your warehouse system records physical movements like picks, putaways, and cycle counts.

Without real-time synchronization, these systems diverge within hours. Batch updates that run overnight mean you're always working with yesterday's information.

The cost shows up in emergency freight charges, frustrated customers (research shows 15-25% won't reorder after their first short-ship), and sales teams who stop trusting the system entirely.

The fix:

Implement bidirectional real-time sync between your eCommerce ERP and warehouse system.

Add an inventory reservation layer that holds stock the moment an order is created.

Use Available-to-Promise calculations that factor in pending receipts and existing allocations.

Translation: When someone hits "buy," that inventory gets locked instantly. Nobody else can grab it. Your systems finally agree on what you actually have.

Customer A negotiated 15% off the list price on one product category. Customer B gets tiered pricing where the unit cost drops at the 100-unit mark. Customer C has blanket purchase order pricing locked until Q2.

None of these pricing rules exist in your e-commerce system.

Sales reps manually create quotes using Excel, checking their notes each time. Industry research shows businesses can cut labor costs by 30-50% through automation. Yet many B2B supply chain distributors still rely on manual quoting that wastes hours every single day.

Quote processing can be reduced by 30-70% with proper integration. That means your sales team could handle three times more opportunities each week instead of building spreadsheets.

The fix:

Sync customer-specific price lists from your ERP to your commerce platform.

Implement a dynamic pricing engine that applies volume breaks, contract dates, and promotional periods in real time.

Enable automated quote-to-order conversion so reps never re-key data.

One distributor we worked with cut quote time from 45 minutes to 4 minutes. Same accuracy. Way more sales capacity.

A customer orders 500 units. You have 200 in stock. The system ships the partial quantity and creates a backorder for 300 units.

When the customer calls asking, "When will I get the rest?", your service rep checks the ERP. A purchase order shows an expected receipt date of March 15. But an email from your vendor yesterday pushed delivery to March 29.

No system automatically shows this updated timeline to your customer. They call. You apologize. They wonder if they should find a more reliable supplier.

Backorders that exist in your ERP but remain invisible in customer portals create unnecessary friction. Studies show that 40% of customers who complain about delivery issues consider switching suppliers.

The fix:

Build backorder visibility into your customer portal with live estimated arrival updates.

Integrate purchase orders with sales backorders in your ERP.

Set up automated notifications when supplier delivery dates change.

Give customers the visibility they're already getting from Amazon. Even if the news is bad, they'll appreciate knowing.

A customer's purchase order specifies detailed requirements. Ship to Site B. Bill to headquarters. Mark boxes with "QC Inspection Required." Include Certificate of Analysis with shipment.

Your e-commerce order captures ship-to and billing addresses. Your ERP records customers, items, and prices. The warehouse pick ticket shows items, quantity, and location.

Special instructions? Lost somewhere between systems. Compliance document? Nobody knew it was needed. Angry customer call? Coming in about 20 minutes.

This happens because custom fields don't map across systems. Order forms don't capture what fulfillment teams actually need. The ERP to warehouse integration only passes "standard" fields that some developer decided on three years ago.

The fix:

Design order forms that collect fulfillment-critical data upfront.

Map custom fields through your entire order flow from website to ERP to warehouse.

Create a fulfillment rules engine that triggers based on customer, product, or destination.

Build document attachment workflows so certificates flow directly to the packing station.

Your customer is tax-exempt in certain states and product categories. Their certificate expires annually. The system charges tax anyway because nobody updated the exemption status.

The customer calls finance, frustrated. Your finance team manually applies a credit and chases down an updated certificate. This scenario repeats 40 times per month across your customer base.

Tax exemption certificates stored in filing cabinets or scattered across email folders create compliance risks that can cost you during audits.

Your ERP doesn't validate exemption status in real time, and your e-commerce platform has no integration with tax compliance tools.

One distributor discovered during an audit that 23% of their exemption certificates had expired 6-18 months earlier. They faced $180K in tax liability plus penalties for uncollected taxes.

The fix:

Integrate with automated tax platforms like Avalara, TaxJar, or Vertex.

Implement certificate management with expiration tracking and automated renewal reminders.

Enable real-time exemption validation at checkout.

Give customers a self-service portal for certificate upload.

Your customer ordered the same 12 items last month. This month, they come back to your site and start from zero. They search for each product individually and rebuild their cart manually.

Or they call your sales rep, saying, "Send me what I got last time." The rep spends 15 minutes pulling order history and re-entering items one by one.

Research shows that 65% or more of orders at some B2B supply chain manufacturers are repeat purchases. Yet systems treat returning customers like strangers walking in for the first time.

The fix:

Integrate ERP order history into your customer portal.

Enable one-click reorder from past invoices.

Offer saved shopping lists organized by job site, season, or recurring need.

Consider subscription or auto-replenishment options for consumable products.

The experience should feel like this: Customer logs in. Sees "Reorder March Invoice." Clicks once. Done. Order flows to fulfillment automatically.

An engineer needs the load capacity specification for a specific bearing. Marketing has partial information in the content management system.

The product manager has the full spec sheet in cloud storage. Sales has an old datasheet from the vendor.

Your customer gets three different answers depending on who they ask. None of them is fully correct. The engineer gives up and calls your competitor.

Without a Product Information Management system, product data scatters everywhere. Your ERP stores transactional data.

Your website has marketing content. Technical specs live in folders. No single source of truth exists anywhere.

Updates made in one place never flow to others. B2B supply chain distributors end up with inconsistent product information across every customer touchpoint.

The fix:

Implement a PIM system as your central product data hub.

Store technical attributes, marketing copy, images, and documents in one place.

Set up automated syndication to e-commerce platforms, ERP systems, and marketplace channels.

Use version control and workflow approvals for product data governance.

Update once. Publish everywhere. Automatically.

Modern integrated systems rely on purpose-built B2B eCommerce solutions that connect ERP, warehouse systems, pricing logic, and customer portals into a single operational backbone.

The warehouse system handles physical operations, including inventory movements, picking, packing, and shipping.

E-commerce platforms like BigCommerce, Shopify Plus, or Adobe Commerce provide your digital storefront. PIM systems manage product content.

CRM platforms track sales pipeline and customer engagement.

Tax compliance platforms automate calculation and exemption management. Payment gateways process corporate card transactions properly.

CPQ systems generate quotes and handle product configuration.

The key is understanding which integrations need real-time sync versus batch processing. Inventory and B2B pricing need real-time updates.

General ledger posting can happen in batch mode at the end of the day.

According to industry analysis, 72% of firms have enhanced visibility through cloud-based supply chain platforms. Automation is reducing manual labor by 19% and improving order accuracy rates above 98.5%.

Here's what this looks like in practice for B2B supply chain manufacturers. A sales rep pulls up an account at 4:55 PM. The quote generates in 30 seconds with accurate pricing, live inventory, and automated freight calculation.

They send it. Customer approves from their phone. Order flows to the warehouse automatically.

No re-keying. No errors. No overtime. No heroics required.

We've built these exact integrations at Reveation Labs for manufacturers and distributors tired of manual workarounds. The systems we connect don't just pass data back and forth.

They actually understand your business rules.

B2B integration projects crash when IT teams lead without business input. They build technically correct integrations that don't match how the business actually operates.

Vendor lock-in with proprietary middleware means you can't adapt when business rules change. Without data governance, you get garbage in and garbage out, which creates distrust.

Under-scoped error handling causes systems to break silently. Nobody notices until customers start complaining.

The better approach starts with business process mapping before technical architecture. Use modular, standards-based integration approaches.

This is where experienced B2B ecommerce consulting makes the difference, aligning business processes with technical architecture before a single integration is built.

Implement comprehensive logging and monitoring dashboards. Most importantly, maintain joint accountability with business owners for outcomes, not just technical deliverables.

B2B supply chain distributors who get this right see payback in months, not years.

At Reveation Labs, we speak the language of B2B supply chain manufacturers and distributors. We understand minimum order quantities, case packs, and pallet configurations.

We know a lot tracking, serial numbers, and expiration dates matter. We've built systems handling drop ship, cross-dock, and transfer orders.

We've integrated warehouse systems for distributors managing multiple locations. We've built CPQ solutions for configurable products with thousands of option combinations.

Beyond implementation, ongoing eCommerce maintenance ensures integrations stay stable as pricing rules change, new warehouses are added, and systems evolve.

We've connected ERPs to B2B e-commerce platforms processing thousands of orders monthly.

Here's what makes us different. We start with process mapping sessions with your operations teams. We build integrations that handle the edge cases that break standard systems.

We focus on operational reality, not vendor demonstrations. Support continues post-launch until your teams are confident and self-sufficient.

We don't just connect your systems. We make sure they actually work the way your business operates.

Here's what changed recently. Your competitors aren't just planning these integrations anymore. They're already seeing results.

The distributor who can quote in 30 seconds beats the one who needs 48 hours every single time.

The manufacturer with real-time inventory wins the sale over the one who "needs to check the warehouse." According to ROI data, businesses typically pay back their connected commerce investment in 3.3 months.

They generate 5-7 times ROI within 3 years.

Time spent on invoice management drops by 75%. Digital revenue increases by 20% from new and existing B2B buyers.

These aren't projections. These are actual results from B2B supply chain manufacturers and B2B supply chain distributors who stopped accepting manual workarounds as normal.

Every month you wait, your manual processes cost more, and your competitors pull further ahead.

The manual workarounds you've normalized aren't normal. They're expensive, fragile, and completely preventable.

Your supply chain deserves better than duct tape and daily heroics.

If three or more of these problems made you wince, let's talk. We offer a thorough integration diagnostic that maps your current systems and data flows.

We identify the top friction points costing you the most money. We outline integration architecture options and provide realistic timelines.

At Reveation Labs, we've helped B2B supply chain manufacturers and distributors eliminate these exact problems. Your systems should work for you, not against you.

An integrated backbone lets you scale without the chaos.

The question isn't whether to fix these problems. The question is how much longer you can afford not to.

Sara Ali

Thu Dec 18 2025

Sara Ali

Thu Dec 11 2025

Sara Ali

Tue Dec 9 2025

Sara Ali

Wed Dec 3 2025