B2B eCommerce is booming, and buyer expectations are changing fast. Gartner predicts that by 2025, about 80% of B2B sales interactions will be digital. In practice, this means enterprises must deliver an Amazon-like buying experience, including real-time inventory visibility and rock-solid retail fulfillment. On-time delivery is often a buyer’s top performance metric. If you can’t promise accurate stock levels and fast shipping, you risk losing those buyers.

Imagine clicking “Buy” only to have the site tell you the item is out of stock – that’s a sure way to lose a sale. Modern B2B managers know that accurate stock information isn’t always optional; it’s table stakes. Real-time APIs linking your ERP and eCommerce platform are now the baseline for efficient selling.

For example, one industry source notes that understanding what is inventory management and implementing real-time inventory updates let you avoid stockouts and backorders. It’s no wonder vendors of niche platforms brag about it. An electrical-supply commerce platform, for instance, advertises that it “integrates with ERP systems for real-time inventory and pricing”.

Similarly, automotive eCommerce analysts stress that up-to-the-minute stock data is essential for profitability. High-volume industries like auto and electrical parts simply can’t afford to let inventory go stale – buyers demand the truth about stock availability now, not later.

The Modern Buyer Expects Real-Time Inventory Across All Locations

In fields like auto parts distribution or electrical supply, downtime is costly. B2B buyers in these sectors often handle urgent orders for replacement parts or components, and they expect to see exactly what’s in stock. This means your eCommerce site must pull live inventory data from every warehouse, leveraging robust warehouse inventory tracking, not just show a cached number. Legacy sites that rely on batched syncs or delayed ERP updates will disappoint customers. Today’s buyers treat B2B sites like B2C giants: they want to check availability instantly, even when ordering a complex multi-sku cart.

To meet this demand, modern eCommerce platforms and advanced ecommerce inventory management software lean on tight ERP integration and real-time APIs.

For example, one software platform tailored to electrical distributors explicitly “supports complex product catalogs, integrates with ERP systems for real-time inventory and pricing,” and provides efficient portals for order processing. In other words, they built their system around livestock data from day one.

Likewise, auto parts merchants use specialized tools for “real-time inventory updates” because those updates are a necessity for an efficient, profitable online store. Simply put, seamless ERP ⇔ storefront syncing is no longer a bonus – it’s a must. Without it, your product listings could be lying to your customers, and you’ll see the price in lost sales.

Also Read: B2B eCommerce for Manufacturers

Multi-Warehouse Logistics: Complexity That Legacy Platforms Can’t Handle

Handling multiple warehouses or fulfillment centers adds another layer of complexity that many legacy systems weren’t built for. Picture a single SKU stocked in six locations: each warehouse has its own inventory count, safety stock levels, and maybe even region-specific regulations or shipping rules. Coordinating that by hand or with an archaic system is a recipe for chaos. As one logistics expert puts it, “managing inventories across multiple locations is challenging” – but when done right, especially with automated inventory operations, it actually builds supply-chain resilience.

Modern B2B platforms acknowledge this head-on. For instance, OroCommerce (a B2B eComm platform) includes built-in support for multi-warehouse inventory management. It can prioritize which warehouse to fulfill from, enforce backorder rules per location, and always sync availability to the storefront. (Others like Virto Commerce and advanced OMS/OMS solutions are similarly designed for these multi-node scenarios.) Legacy eCommerce tools, by contrast, tend to treat inventory as if it were in one giant silo.

They often have no concept of “ship-from location,” meaning a simple regional order can turn into a scheduling nightmare. In practice, companies find that without a purpose-built solution, they can’t easily route orders to the nearest warehouse or comply with differing regulations.

This inflexibility often leads to oversights and unhappy customers. In short, if your platform isn’t built for a distributed fulfillment network, it will struggle to handle the real-world demands of multi-warehouse logistics.

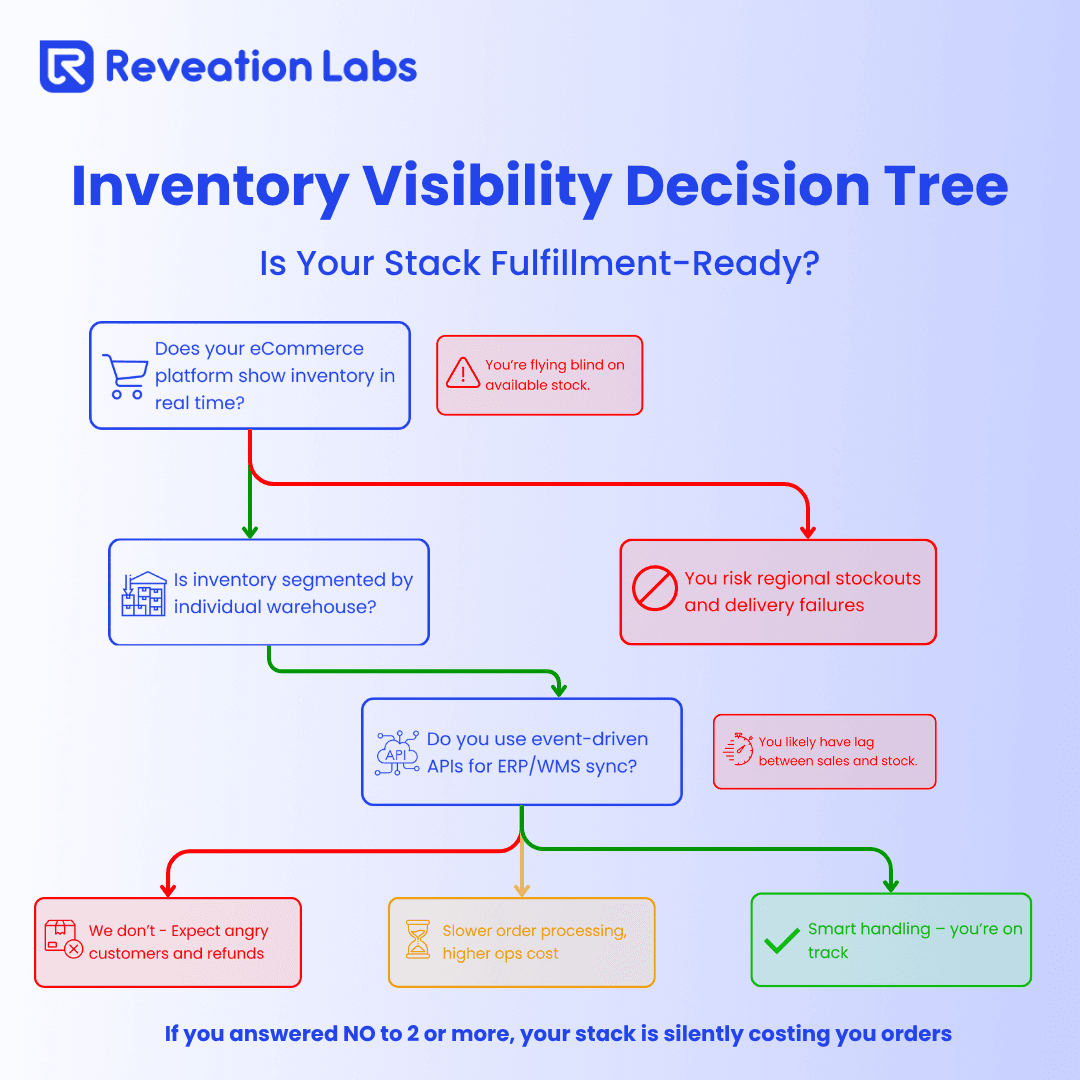

Common Failures in Inventory Sync

The most common inventory headaches happen when sync methods lag or break. If your system only updates stock levels in batches (say, once an hour or at night), you invite overselling during busy times. In fact, one eCommerce expert warns that with “every 30-minute or once a day” batch updates, “you’re still at risk for overselling”.

Equally dangerous are manual workarounds: juggling Excel spreadsheets, CSV uploads, or one-off inventory overrides. As one blog bluntly notes, real-time inventory is “difficult to handle manually while dealing with large inventory across multiple channels”. Each human edit or delayed upload opens the door to errors.

- Batch updates: Traditional connectors and integrations often just “batch sync” inventory periodically. During high-demand periods, this lag means some customers will order items the system thinks are in stock, only to find out later they’re not. The result? A dreaded out-of-stock notice after purchase, cancelled orders, and lost trust.

- Spreadsheets and manual uploads: Some teams resort to manually exporting inventory counts and re-uploading them. This is laborious and error-prone. Typos, timing mismatches, and skipped steps are inevitable. A single forgotten update can leave a page showing phantom stock.

- Quick fixes & overrides: Sales reps or managers might manually override an order or inventory count to push a sale through. But these one-off changes break the data chain. Other systems don’t see the update, so one channel might ship the same unit twice.

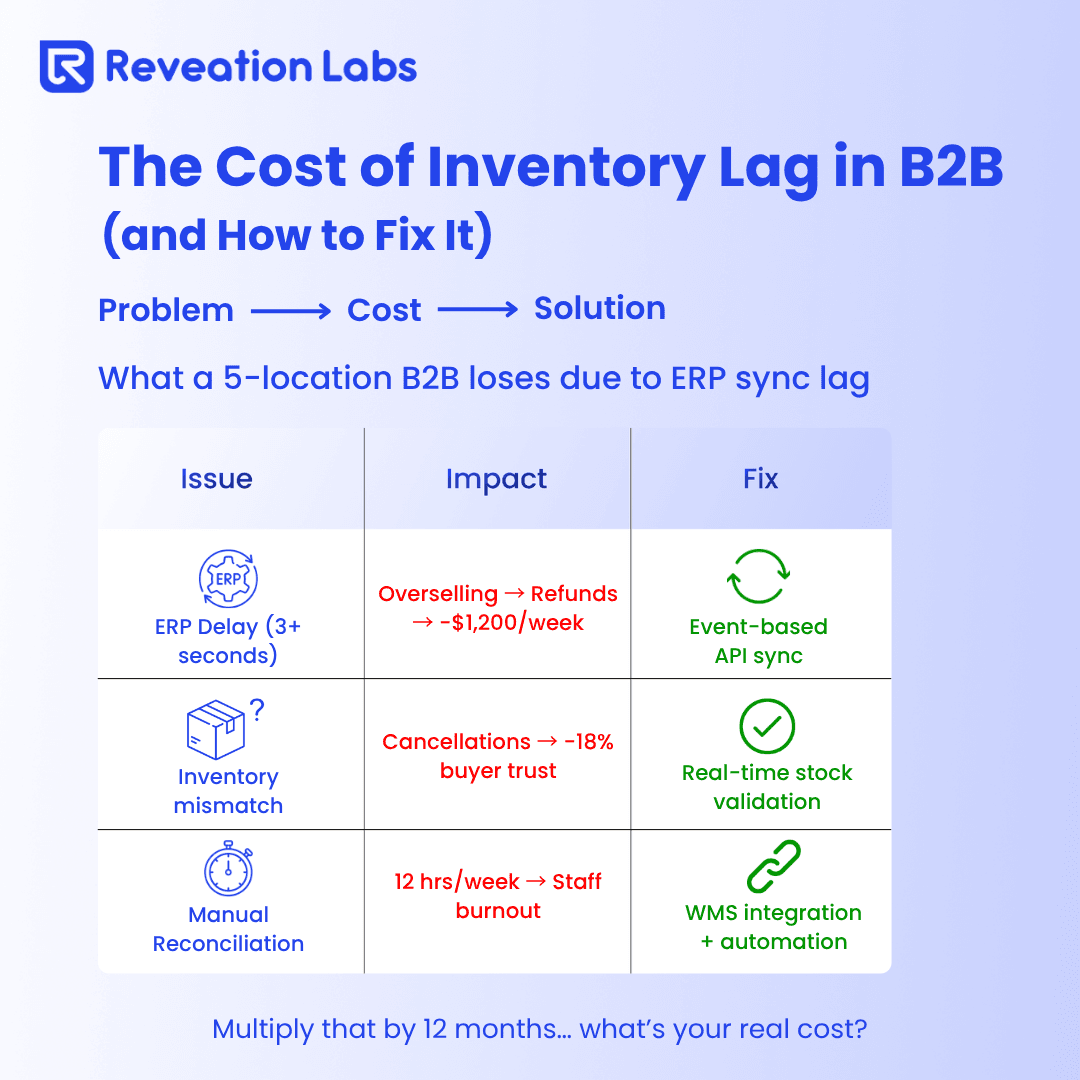

The Cost of Poor Inventory Management

Legacy inventory systems don’t just frustrate buyers, they erode profits. Consider the hidden costs:

- Lost Sales & Cart Abandonment: A Baymard Institute study found that the average cart abandonment rate is 70.19%, with 13% of shoppers abandoning carts due to website performance issues, including stock uncertainty. For a $10M/year business, that’s potentially $1.3M in lost revenue.

- Excess Inventory Overhead: Without real-time visibility, businesses over-purchase "just in case." The National Retail Federation reports that overstocks cost retailers $50B annually in carrying costs and markdowns.

- Customer Churn: A Chain Storeage survey notes that 85% of buyers will switch brands after just one bad delivery experience, often tied to inaccurate stock promises.

These failures all share a pattern: they confuse customers and staff. Imagine someone orders a big chunk of parts online, only to get a “Sorry, we’re out of stock” email after the sale was supposedly confirmed. It’s like selling tickets to a sold-out concert. Not only does it frustrate the buyer, but it also chases them to your competitor.

In the worst cases, it triggers cart abandonment: shoppers leave a cart over fulfillment or delivery issues. (Overselling and stock errors feed right into that frustration.) In short, outdated sync methods kill conversion rates and tarnish your customer experience.

What to Look For in a Platform (Reveation Labs POV)

In choosing a new eCommerce stack, think beyond basic features. Here are three key factors we emphasize at Reveation Labs for real-time inventory success:

- Event-driven architecture: Look for a platform built on events or pub/sub. Every inventory change (sale, return, restock) should trigger an immediate update across all systems. In practice, this means using webhooks or message queues so that when an order is placed, the inventory is updated everywhere instantly, not minutes or hours later. Real-time event streams keep systems in sync without polling or manual jobs.

- Per-line-item availability: Your site should expose inventory at the most granular level – the specific SKU or variant that a buyer is ordering. For example, if a customer is building an order line-by-line or editing a quote, the system should show stock per line item, even for kits or bundles. That way, sales reps or buyers see exactly what’s on hand for each item before checking out. Accurate line-item stock visibility prevents surprises later.

Tight WMS/OMS integration: The platform must tightly integrate your Order Management (OMS) and Warehouse Management (WMS) systems, or effectively manage third party inventory management solutions. For instance, Pivotree explains that when an OMS is fully hooked into the WMS, it can “update each warehouse’s stock levels, making it the primary source of up-to-date information for sales channels”. With this kind of integration, the OMS is effectively the truth-teller for inventory everywhere. In fact, Fluent Commerce (another OMS) touts “accurate and near real-time inventory availability across multiple locations” as a core feature. When OMS and WMS share data this tightly, there’s essentially no risk of overselling, and your storefront always sees the real stock.

Maximize efficiency with B2B eCommerce Consulting, ensuring your platform is built to handle real-time inventory and multi-warehouse wholesale fulfillment seamlessly.

How Real-Time Sync Works

Real-time inventory isn’t magic, it’s architecture. Here’s how systems eliminate lag:

- Event Triggers: When an order is placed, an event (via webhook or message queue like Kafka) notifies all connected systems.

- ERP Deduction: The ERP reduces stock counts and flags pending allocations.

- WMS Reservation: The warehouse management system (WMS) locks the item for picking, updating location-specific counts.

- Storefront Sync: The eCommerce platform reflects the change globally in under a second.

Modern B2B solutions often include these capabilities out of the box. If you have to bolt on middleware to achieve them, you may still face delays.

Always ask vendors: “How does your system handle inventory updates? Do you use events or scheduled syncs? Can we see line-item availability in the cart? How real-time is your WMS integration?” The answers will separate legacy holdovers from next-gen platforms.

Conclusion

In B2B eCommerce, fulfillment can no longer hide in the back office – it’s a competitive edge. Retailers that master real-time inventory visibility and fast multi-node fulfillment win loyalty and market share. If you’re not confident your stack can keep pace, it’s time to audit and modernize.

Reveation Labs works with B2B brands to assess their technology and upgrade order/inventory systems. Our B2B eCommerce expert can help ensure your ERP, OMS, and eCommerce platform communicate seamlessly in real time. After all, in the race for B2B buyers, accurate stock and on-time delivery are not just nice extras – they’re the baseline that buyers expect.